Project Overview

H.Stars Group has recently designed a project for Forest Products Technology Co., Ltd. This project is for the deep processing of 9,500 tons/year of turpentine and 6,500 tons/year of rosin (Phase I). The design primarily focuses on the condensation and recovery of organic solvents in the VOC tail gas.

Project Requirements

Process chilled water: 50m³/h, supply and return water temperature: 12/17℃, water supply pressure: 0.4MPa

Design Proposal

This project design uses a 40STD-370WSI4 water-cooled chiller unit with a dual-cycle design and a 15m³ intermediate buffer water tank. The process water supply pump adopts constant pressure frequency conversion control, and the screw chiller is automatically loaded and unloaded under the temperature control of the intermediate buffer water tank.

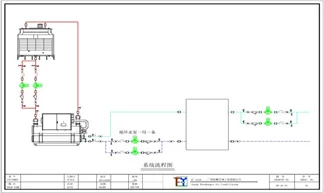

Project System Diagram

Solution Advantages

1. Adopt a special screw-type industrial chiller, establish a dual-cycle system, with the unit's energy efficiency ratio over 6.0 and overall energy efficiency ratio up to 13, and low operating energy consumption.

2. After the completion of the project, the recovery rate of organic solvents in the VOC tail gas is as high as 90%.

3. The entire system uses fully automated control, automatically starting up based on temperature changes, reducing energy consumption.

4. This project includes a centrally integrated computer room and centralized management to minimize investment and operational management costs.