Hot Spring Hotel Resort Center Water Source Heat Pump Solution

According to the high residual temperature of the hot spring overflow, it is used as the water source for the low-temperature side of the water-source heat pump in the winter. Compared to a traditional air-conditioning system, the initial investment and operational costs will be reduced. Additionally, a method for calculating the overflow temperature of the central bath is proposed and discussed. The parameters and characteristics of the hybrid water source and DC methods are detailed.

Principle of Water Source Heat Pump

Heat is transferred from a high temperature to a low temperature. A heat pump is a type of device that increases heat by transferring it from a low-temperature environment to a high-temperature one. It consumes a small amount of electrical energy during operation, but extracts 4-7 times more thermal energy from the environment to raise the temperature. This is why heat pumps are energy-saving. The main components of a heat pump include the compressor, evaporator, condenser, and expansion valve. The principle is as shown in the image below:

Compressor: It compresses and transports the working medium from low temperature and pressure to high temperature and pressure. It is the heart of the heat pump unit.

Evaporator: A device that generates cooling power. Its function is to evaporate the refrigerant flowing through the expansion valve to absorb heat for cooling purposes.

Condenser: A device that generates heat. Heat is absorbed from the evaporator, along with the heat transferred by the work of the compressor, and is carried away by the cooling medium in the condenser to achieve heating.

Expansion Valve: It reduces the throttling effect on the circulating working liquid and takes the circulating working liquid into the evaporator.

When the heat pump heats up, energy stored in the environmental medium is absorbed in the evaporator, and heat is released from the condenser through the liquid working medium circulation system. The energy output of the heat pump is the work done by the compressor and the heat absorbed from the environment. As we can see, the use of heat pump technology can save a lot of energy.

Types of Heat Pumps

Heat pump units are mainly divided into two types: air-to-heat exchangers and water-to-heat exchangers, according to the difference between the evaporator device and the surrounding medium. Heat pumps can also be classified as water-to-water based on the difference in heat transfer environment. There are four types: water-to-air, air-to-air, air-to-water. If heat pumps are categorized by the nature of the cold source and low temperature, heat pump systems can be divided into two types: air-source heat pumps and ground-source heat pumps. A water-source heat pump uses water as the heat source, while a ground-source heat pump uses the ground. According to the current national standards for ground-source heat pump units, and the building's internal systems, the ground-source heat pump system is divided into three types: closed-loop, open-loop, and surface water-based systems.

Advantages of Water Source Heat Pumps

Compared to traditional air-conditioning and heating systems, water source heat pump systems offer the following advantages:

1. **Renewable Energy Source:** Water-source heat pump technology is a renewable energy technology. It uses the geothermal energy from the surface of the earth as the cold and heat source to convert energy. It is not restricted by geography and resources, and is omnipresent.

2. **Energy Efficiency:** Water-source heat pumps are highly efficient energy-saving technologies. The temperature of underground geothermal resources or surface resources remains stable throughout the year. In the winter, the temperature is higher than the surrounding air, and in the summer, it is lower. This is an excellent heat source for heat pumps and air conditioning. This temperature characteristic makes ground-source heat pumps 40% more efficient than traditional air-conditioning systems, leading to about 40% savings in operating costs.

3. **Environmentally Friendly:** Water-source heat pumps significantly benefit the environment. The emissions from water-source heat pumps are 40% lower than traditional air-conditioning systems. Compared to electric heating, it reduces emissions by more than 70%. When combined with other energy-saving measures, the energy savings and emissions reduction are even more significant. While refrigerants are used, the amount is 25% lower than traditional air-conditioning systems. This is a closed-loop system, meaning that the equipment can be completely sealed within the factory floor, significantly reducing the chances of refrigerant leaks.

4. **Versatility and Reliability:** Water-source heat pumps can be used for both heating and cooling, and can also provide hot water for various applications. A single unit can replace three systems: central heating, air conditioning, and hot water. They are suitable for use in hotels, hospitals, factories, office buildings, and residential facilities.

Water Source Heat Pump Application Conditions

Heat pump technology is a new energy-saving and environmentally friendly technology. Compared to other systems, it offers high advantages. However, the following aspects should be noted during application:

1. **Low-temperature Heat Source:** The key principle in applying the heat pump system is to adapt to local conditions. According to project requirements, low-temperature heat sources such as shallow groundwater, rock, and earth, seawater, river water, and residual hot spring water should be used. It is best to use low-quality heat sources.

2. **National Policy:** For shallow groundwater or geothermal water, to ensure resource extraction is done in an orderly manner and to prevent land subsidence, the state has set policies requiring 100% of the water to be replenished.

Hot Spring Hotel Resort Center Water Source Heat Pump Solution

Project Background

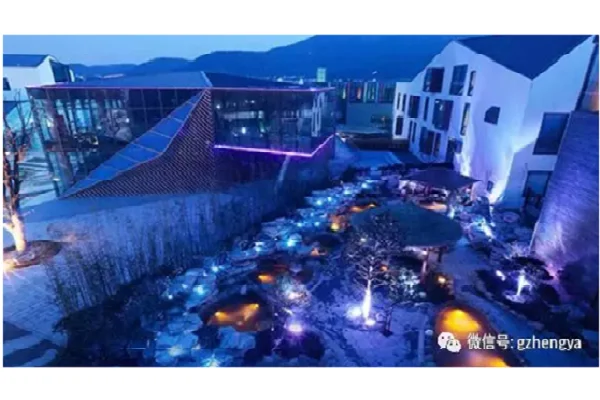

**Project Overview:** The Hot Spring Hotel Resort Center is a business resort hotel with a total area of 92,860 square meters, including 23,436 square meters of built-up area, 12,207 square meters in the hotel’s public area, 8,749 square meters for guest rooms, and 763 square meters over the sea. The geothermal hot spring water temperature is approximately 70°C. The plan is to use a central water source heat pump air-conditioning system to cool the hotel in summer and heat it in winter. The water source uses geothermal hot spring tailwater. Due to the special function of the hotel, there is a high demand for hot water, and tailwater is collected from the building. The heat source for heating and cooling towers is used to cool in the summer, implementing a dual-use system for one machine, reducing system investment and operation costs.

2. Meteorological Conditions

Atmospheric Pressure: 1026.6Kpa in winter and 1004.8Kpa in summer.

Average Outdoor Wind Speed: 3.0m/s in winter, 2.6m/s in summer, and average wind speed of 6m/s in winter.

Outdoor Dry Bulb Temperature: -9°C in winter, -4°C in winter, -11°C in winter, 33.4°C in summer, 29°C in summer, and 29.2°C in summer.

Outdoor Wet Bulb Temperature: 26.9°C in summer cooling.

Outdoor Relative Humidity: 53% in the coldest month of winter and 78% in the hottest month of summer.

3. Design Load

According to the cooling and heating load provided by the design institute for the project:

Cooling Load Index: 110 watts/square meter, total cooling load is 2578 KW, heating load index is 70 watts/square meter, and total heating load is 1641 KW.

4. Unit Selection and Operation Plan

1) Equipment Selection: Based on the overall technical guide for cooling heat pumps, the building's cooling load and macro water source model, the following models and quantities of units are selected: 2 water source heat pump units (cooling capacity 1330KW, heating capacity 205.5KW; cooling capacity 1528KW/unit, heating capacity 290.2KW/unit).

Cooling Water Temperature Input/Output: 12/7°C, Heating Water Temperature Input/Output: 18/29°C; Winter Heating: Heating Water Temperature Input, Output 40/45°C, Source Water Hot (Groundwater), Output Water Temperature 15/7°C.

During summer, cooling towers are used. Working conditions are 32/37°C, 12/7°C. Under these conditions, the unit's cooling capacity is 1266KW and heating capacity is 237.5KW.

During winter, the tailwater temperature is 30°C (or higher). Common units cannot handle such high water temperatures, and heat exchange is required for the heat exchanger. The primary water temperature is 30/13.5°C, the secondary water temperature is 12/20°C, and the primary flow rate is 80 m³/hour. The secondary flow rate is 165 m³/hour.

2) Unit Operation Plan

The primary heat pump unit selected in this diagram is a high-efficiency energy-saving heat pump air-conditioning unit. Each heat pump unit consists of two compressors, all with independent systems, meaning each compressor has its own water system, separate oil system, refrigeration system, and electrical control system. One system failure does not affect the other systems.

In actual use, the speed of the unit can be better adjusted according to the building’s actual load, and different categories can be loaded to reduce operating costs. The equipment can automatically adjust the number of operating stages according to changes in outdoor climate, heating, and cooling loads to achieve the most economic operation.

All units are fully intelligent and controlled automatically via PLC-based computer systems. The equipment can set temperature and time, automatically load or unload according to preset parameters (variable frequency operation 12.5-100%). The system also includes automatic fault protection, alarm functions, automatic recording, and auto shut-off to protect the equipment and aid troubleshooting.

System Configuration Diagram

1) Computer Room System:

The computer room system is designed for both aesthetics and practical functionality and operational capability. The system uses water to soften and soften water after automatic softening by a water softening machine. The system uses constant pressure pumps + softened water for water replenishment.