Changes in Chilled Water of Industrial Refrigeration Systems

Manufacturing enterprises often require chilled water for cooling during production. Due to the impact of the production process, market output, and other factors, the demand for chilled water is generally large. In this case, it is essential to design a targeted chilled water circulation system.

The conventional chilled water circulation system delivers chilled water to the production water points after being chilled by the chiller, and then it returns to the chiller to complete the system's closed loop. However, when the system's water consumption changes significantly, this system will cause the chiller to malfunction. With years of experience in industrial project services, we have designed a solution to address the changing demand for chilled water.

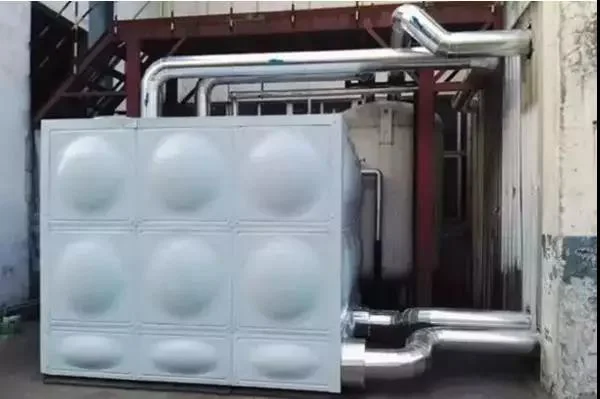

In the dual-circulation system, a chilled water tank is configured to store water. The tank is divided into high and low-temperature zones, and the system is divided into an external circulation system and an internal circulation system.

The external circulation system mainly includes the water points, chilled water pump process, and frozen water tank. The pump distributes water from the low-temperature zone of the frozen water tank to the water points and then returns to the high-temperature zone of the water tank after being cooled. The pump uses frequency conversion pressure control, automatically adjusting the frequency conversion, ensuring safer operation and energy efficiency. The internal circulation system mainly includes the frozen water tank, refrigeration pump, and chiller. The water is pumped by the frozen water pump from the high-temperature zone of the tank, chilled by the chiller, and then returns to the low-temperature zone of the tank.

With this chiller system, the water flow to the chiller is not significantly affected by the changes in chilled water usage in production, and the water tank provides a certain amount of cold storage, effectively solving the problem of frequent chiller starts and abnormal chiller operation. The system is not only safe and reliable but also highly energy-efficient. The circulation pump moves water from the high water tank to the chiller, and after being chilled, the water returns to the low-temperature zone of the water tank, increasing the chiller's efficiency by 15%. The pump applies frequency conversion control technology to better meet changes in water consumption while also efficiently consuming less energy.