Ⅰ. Demand Situation

This is a project for the ice water system of a food and beverage company. The ice water systems primarily meet the ice water requirements on the production line. The required ice water temperatures are two: one is 5°C ice water; the other is -5°C ice water.

ⅱ. Load Calculation

1. The total cooling capacity for 5°C ice water is 1500KW;

2. The total cooling capacity for -5°C ice water is 750KW;

3. Ice water storage tank configuration 12-℃: 2 insulated stainless steel storage tanks of 15M3;

4. -5°C ice water storage tank configuration: 2 insulated stainless steel storage tanks of 15M3.

ⅲ. Design Concept

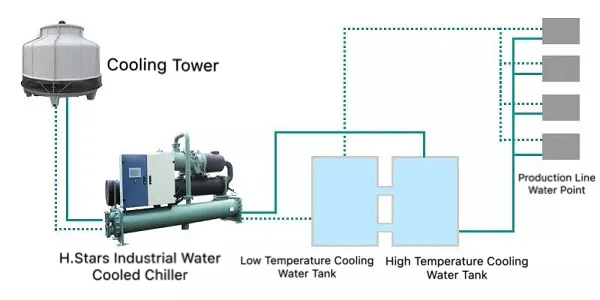

Since the required temperatures for the ice water differ according to the production line, and the amount of cooling water required for different ice water temperatures does not differ much, the system is designed to reduce operational costs. Therefore, the cooling system and ice water system are selected according to the different temperatures.

ⅳ. Equipment Selection

1. Main Unit: For the 5°C ice water system, the industrial water-cooled chiller H.Stars (model 40STD-2020WDI2, cooling capacity 2016KW, input power 348.4KW) was selected.

2. Main Unit: For the -5°C ice water system, the industrial water-cooled chiller H.Stars (model 40STD-1090DSM2, cooling capacity 824KW, input power 239.9KW) was selected.

H.Stars Industrial Water Chiller

3. One unit of 5°C ice water chiller and cooling tower.

4. One unit of -5°C ice water chiller and cooling tower.

5. Cooling water pumps:

Two units of 5°C ice water chillers and cooling water pumps;

Two units of -5°C ice water chillers and cooling water pumps;

6. Cold water pumps:

Two units of 5°C ice water chillers and cold water pumps;

Two units of -5°C ice water chillers and cold water pumps.

ⅴ. Usage & Control

1. The usage and control modes of the 5°C and 5°C ice water systems are identical, divided into the cooling system, internal ice water circulation system, and external ice water circulation system.

2. The chiller, cooling tower, cooling water pump, and cold water pump operate in a one-to-one mode.

ⅵ. System Advantages

1. High efficiency and energy-saving:

1.1 With the double water tank system, the water temperature of the unit is higher (5 degrees higher than the single tank system), and the unit’s efficiency is higher (15% higher than the single tank system).

1.2 The cooling tower and water pump of the equipment are in a one-to-one mode, effectively reducing the operational cost of the supporting crew.

2. Easy to use and long lifespan:

2.1 The supporting equipment, cooling tower, and water pumps apply the one-to-one mode, making operation simple and convenient, improving the overall lifespan of the equipment;

2.2 The equipment uses a microcomputer controller, with features like phase loss, reversal, overload, high and low protection, fault querying, error analysis, memory, and other functions, making it easy to use and manage maintenance.

ⅶ. Energy-saving Analysis

1. Using double water tanks increases electricity savings due to the evaporating temperature

Using double water tanks to increase the evaporating temperature helps save electricity costs, determined by the performance of the compressor. According to the compressor's performance parameters, under the same condensation temperature, each increase in evaporating temperature by 1 degree saves approximately 3.3% of the cooling power. The double water tank can increase the evaporating temperature by 5 degrees, thus the cooling capability can increase by about 16.5%. Based on the average load speed of the unit over 5000 hours per year, the electricity cost will be reduced by $52,000.

2. The cooling tower and water pump of the equipment are in a one-to-one mode, relating to the production load speed

ⅷ. Conclusion

1. Plants that require both cooling water and hot water for sanitation are used not only in pressure industries and plastics but also in pharmaceuticals, electronics, electroplating, chemicals, dairy, PV, food, refrigeration, textiles, and other industries.

2. If heat recovery is available, the owner can use a heat recovery unit. If the temperature is insufficient for heat recovery, supplementary heating equipment or a heat pump unit with full water heat recovery can be chosen.